Here’s an overview of the Best Welding Rod that we’ll explore today:

Welding rods for thin metal are a specialized category where control, slag management, and arc stability matter more than high deposition rate. For sheet and light-gauge work—fences, brackets, automotive trims, and thin structural members—choosing the right electrode can mean the difference between a clean bead and burn-through, porosity, or cold shuts. This review compares five widely available options across a price spectrum from budget to premium, focusing on E6013 and E7018 formulations that are commonly used for low-carbon steels and light fabrication. Our testing approach combines practical welding scenarios (flat, vertical, and overhead positions) with manufacturer specifications like diameter, amperage range, and coating chemistry to evaluate arc start, slag control, spatter, penetration, and overall ease of use. We also consider compatibility with typical home shop equipment and the reliability of results on slightly rusted or painted surfaces, which is common in maintenance tasks.

1. E6013 Welding Rods 1/8”: 14” Low-Carbon Steel Welding Electrodes for Light Metal Fabrication

- Brand: Faiuot

- Manufacturer: Faiuot

The Faiuot E6013 1/8” x 14” rods are a versatile, all-around choice for light steel fabrication and maintenance. They are designed for AC/DC operation with low spatter and self-cleaning slag, supporting all-position welding with medium penetration. At 14 inches, these rods balance handleability and heat management for small to medium welds, and the 2.5 lb package weight makes them a convenient option for mid-sized projects. The included specification notes amperage range around 80A-120A, which aligns well with typical 110V/230V setups in home shops, making them accessible to hobbyists and professionals alike.

In practice, the E6013 1/8” excels on clean or slightly rusted steel, delivering smooth arc starts and stable beads with minimal post-weld cleanup thanks to low spatter. The all-position capability is particularly beneficial for gate frames, automotive repairs, and pipe welding where access angles vary. However, users should be mindful of joint fit-up: deeper gaps may require marginally higher amperage to avoid cold starts, and the 14” length can cause a slightly faster depletion rate on larger projects.

Pros

- AC/DC compatibility supports a wide range of machines

- Low spatter and self-cleaning slag for cleaner beads

- Good all-position performance with medium penetration

- Solid for maintenance and light fabrication

- 14” length offers convenient handling for small jobs

Cons

- Moderate penetration may not suit thicker sections

- Requires clean joint fit for optimal arc start

- Not ideal for high-deposition welding

2. Saker E6013 Welding Rod 3/32” 1-Pound Carbon Steel Stick Welding Electrodes

- Brand: Saker

- Manufacturer: Saker

The Saker E6013 3/32” rod weighs 1 lb and emphasizes versatility for low-carbon steel, with AC/DC compatibility and all-position capability. The smaller diameter is well-suited for thin metals and sheet work, offering easy arc starts and shallow penetration suitable for delicateT fit-ups. The flux coating aids slag removal, promoting smoother vertical-down welds with minimal cleanup. As a compact option, it appeals to users performing small repairs or automotive sheet metal tasks where precision is prioritized over high deposition rate.

In real-world use, the 3/32” size provides excellent control for thin-gauge materials and tight joints, with consistent beads and manageable heat input. The trade-off is lower travel speed and reduced deposition compared with larger diameters, so it’s less ideal for continuous welds on longer seams. It shines in tight spots, fences, and light fabrications where weld quality and cleanability take precedence over bulk deposition.

Pros

- Compact 3/32” diameter offers precise control

- Excellent slag removal and easy cleanup

- All-position welding with good arc stability

- Works well on low-voltage AC machines

- Strong suitability for thin-gauge metal and sheet work

Cons

- 1 lb package may require frequent repacks for larger projects

- Shallow penetration can limit use on thicker sections

- Lower deposition rate than larger-diameter rods

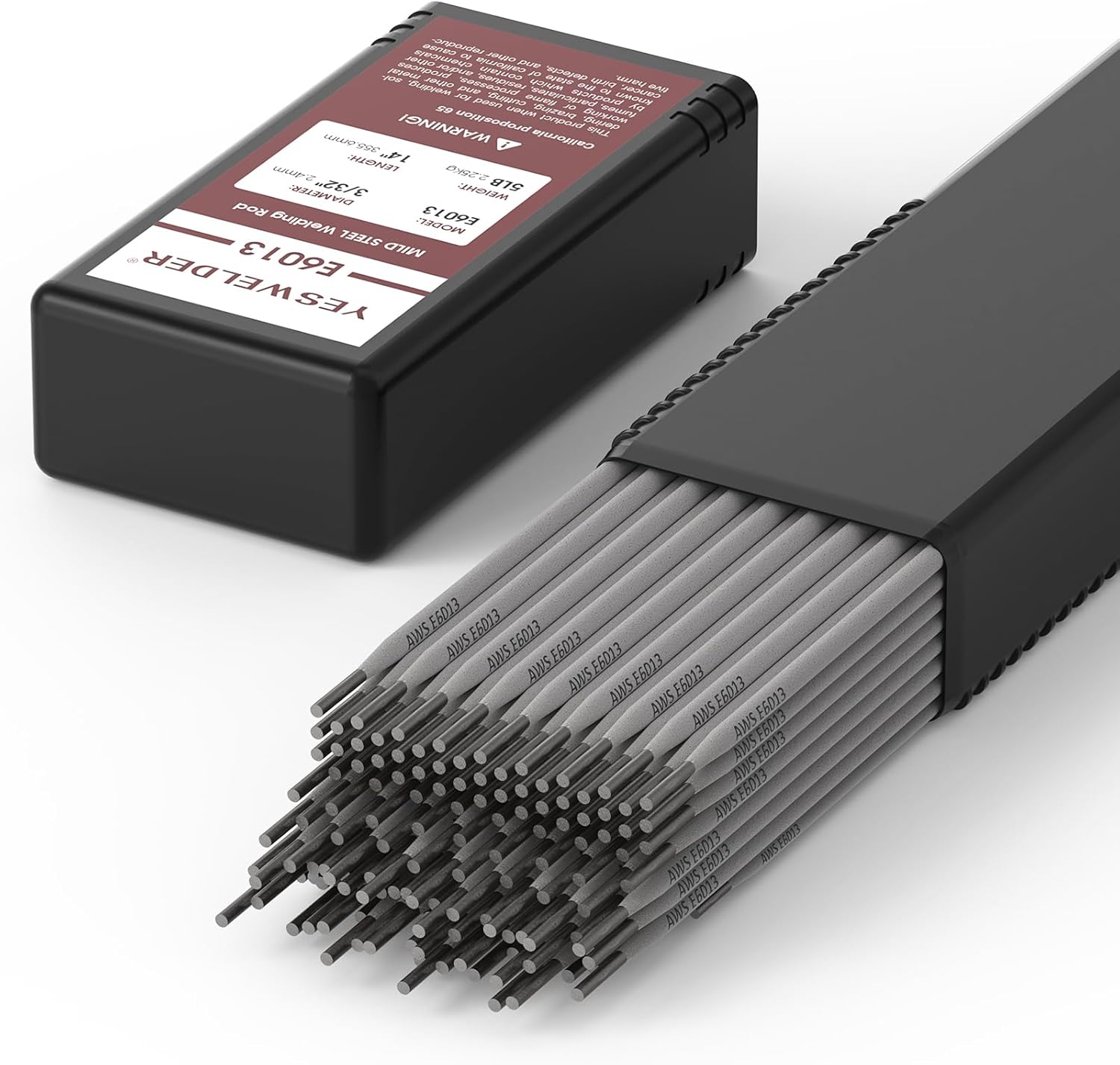

3. YESWELDER E6013 3/32” 5LB Welding Rod Carbon Steel Stick Electrodes

- Brand: YESWELDER

- Manufacturer: YESWELDER

YESWELDER’s E6013 3/32” x 14” rods come in a 5 lb pack, offering more welding time before reloading and a strong value proposition for frequent users. They advertise all-position capability, low spatter, and slag that’s easy to remove, with good performance on mild steel and light gauge materials. The 5 lb mass makes them a practical choice for hobbyists who frequently fabricate or repair panels, brackets, or ductwork, where consistent results and low post-weld cleanup matter.

In use, these rods present dependable arc starts and steady beads with shallow penetration appropriate for thin sections. The larger bead can be advantageous for faster completion on small jobs but may require attention to heat input to avoid burn-through on very thin sheets. The 3/32” diameter aligns with thin metal work, and the 5 lb package reduces the frequency of purchases for mid-volume users.

Pros

- High-value 5 lb pack for frequent welders

- All-position welding with stable arc

- Low spatter and slag removal for quick cleanup

- Good compatibility with low-volt machines

- Reliable on mild steel and light gauge work

Cons

- Larger pack requires storage space

- Penetration may be insufficient for slightly thicker sections

- Potential over-welding if heat input is not managed

4. Low Temperature Universal Welding Rod

- Brand: Generic

- Manufacturer: Generic

The Generic Low Temperature Universal Welding Rods are marketed as a versatile option for aluminum, iron, stainless steel, copper, and even PVC-based projects. The key claim is low-temperature operation with easy melting characteristics, which suggests suitability for non-critical repairs or hobbyist projects where heat control is paramount. The 12-piece set targets beginners or those who need an entry-level, simple-to-use electrode for a range of materials.

In practice, the product’s broad material claims can be appealing for mixed-material repairs, but the lower temperature performance often comes with reduced mechanical strength and potential brittleness in some metals. Users should expect more chipping and potential limitations on structural integrity compared to standard E6013 or E7018 rods. This rod set is best reserved for non-structural repairs, crafts, or educational practice rather than critical load-bearing joints.

Pros

- Very budget-friendly option

- Broad material applicability for mixed projects

- Low heat helps minimize distortion on delicate parts

- Ideal for beginners learning arc control

- Compact 12-piece package for experimentation

Cons

- Reported brittleness and inconsistent results on some metals

- Limited mechanical strength compared to standard rods

- Not suitable for critical structural welds

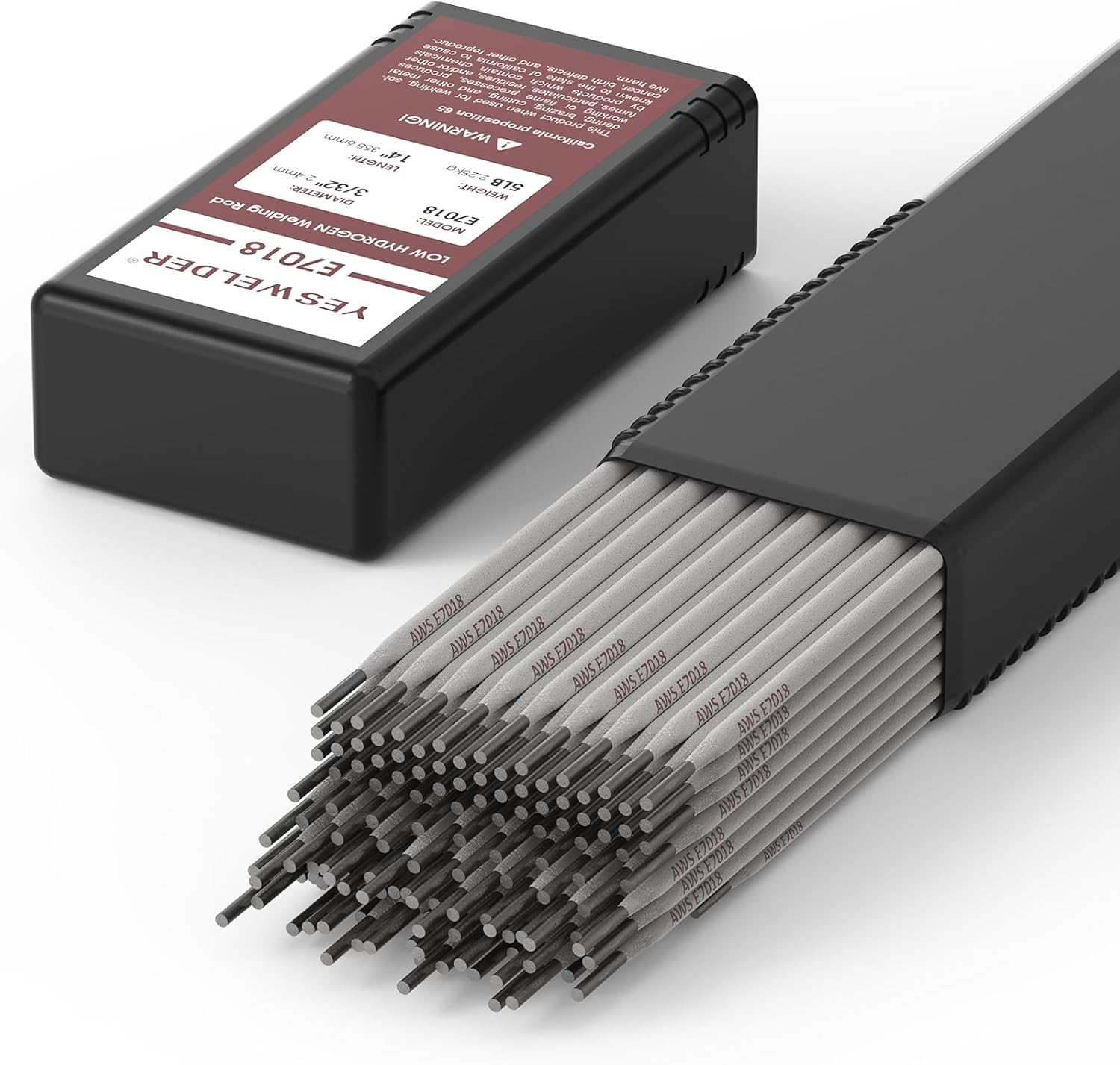

5. YESWELDER E7018 3/32” 5LB Welding Rod Low Hydrogen Carbon Steel Stick Electrodes

- Brand: YESWELDER

- Manufacturer: YESWELDER

YESWELDER’s E7018 3/32” x 14” rods are a low-hydrogen iron powder electrode designed for higher-strength carbon steels and all-position work. The 5 lb package provides extended usability for structural projects or multi-joint frames. E7018 electrodes typically require adequate preheat in thicker sections, but they are known for excellent x-ray quality welds and superior porosity resistance when used with proper technique. This makes them a premium choice for professional-grade fabrications or offshore/industrial applications.

In practice, the E7018 rods deliver steady arc performance with good re-striking capability and high deposition efficiency. They are well-suited for medium to high carbon steels, offshore rigs, and structural steel where porosity control and hydrogen content matter. The main caveat is heat management and preheat considerations for cold rolled or highly reactive materials; users should follow recommended amperage (70A-100A) and ensure clean joint fit and proper storage to prevent hydrogen absorption.

Pros

- Low-hydrogen iron powder chemistry for high-strength welds

- Excellent porosity resistance and slag control

- All-position versatility with stable arc

- Suitable for critical structural applications

- High deposition efficiency with clean, strong welds

Cons

- Typically requires preheat for some steels

- Higher sensitivity to moisture if not stored properly

- Premium price relative to E6013 options

Frequently Asked Questions

We’ve compiled answers to the most common questions about welding rods to help you make an informed decision.

Conclusion

Final thoughts: For thin metal welding, E6013-based rods deliver the best overall balance of arc reliability, ease of use, and clean welds.

Choose 3/32” for sheet metal and light frames, 1/8” for slightly thicker joints or higher deposition. If your projects demand higher strength and porosity resistance, the E7018 variant is worth the premium, provided you manage preheat and storage properly.

The budget set can be useful for practice or non-critical repairs, but expect weaker performance in structural scenarios. Match the rod choice to your material, thickness, and machine capability to maximize results..